As remote working practices become more commonplace – in response to workplace culture shifts, adapting to better work/life balances or unforeseen disruption that requires resilience to overcome – capturing and analysing real-time data from a processing location remotely will become an increasing necessity for agile, forward-thinking process manufacturers and teams.

This necessity can be addressed with the adoption of a robust digital transformation strategy – including the integration of connected smart technology, such as Hosokawa Gen4 intelligent software – to help facilitate team cohesion, simplify problem-solving, enable quick decision-making and maintain operational efficiency.

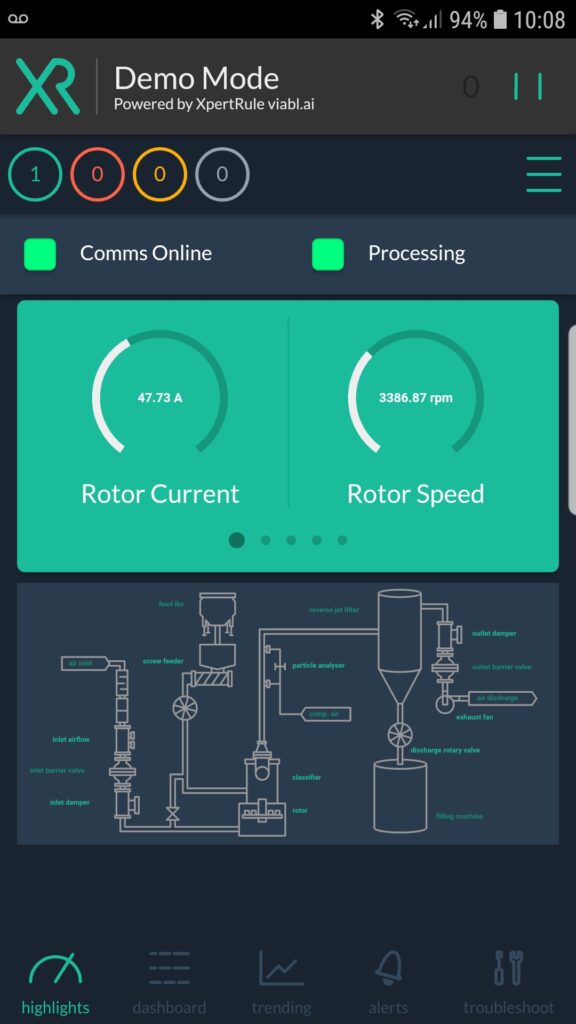

Hosokawa Gen4 incorporates an exceptionally informative, custom-made remote monitoring (ReMs) App as part of its digitalisation solutions to deliver real-time visibility of your plant’s status, providing alerts, practical predictions and prescriptions from the collated and analysed data.

Our experienced process engineers and digitalisation team collaborate to diagnose your operating issues, then inform and train your operators to maximise your plant processes.

Developed by Hosokawa Micron’s expert technology partners, the restricted-access Hosokawa Gen4 App can be loaded onto a computer, tablet or smart phone and is available 24/7 from anywhere in the world to relevant stakeholders.

Our technology experts have created a demo version of the Hosokawa Gen4 ReMs App, specifically for process manufacturers to see how the technology could work for their business.

The demo version can be downloaded for free via the iTunes Store or on Google Play. Simply click here to download your preferred version.

For further information about the Hosokawa Gen4 ReMs App, please click here

Complete a short survey about our website?

Please provide your details to register your interest in the event and we will be in touch soon to confirm the details.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |