To discover more about the services we can offer to support your Hosokawa Micron equipment, please get in touch with our helpful team. For immediate assistance or advice, feel free to give them a call on:

Our expert digital solutions team can transform your data into easy-to-understand, practical and dynamic sensor and control models, based on your specific KPIs and operating parameters.

These models allow you to maintain, evolve and improve the performance of your processes, equipment and systems to deliver tangible business benefits that lead to more lean manufacturing and, ultimately, greater profitability.

Uniquely, Hosokawa Gen4 sensor and control models are entirely bespoke and can be custom-built for your existing integrated processes or developed from our library of best practice KPIs and solutions to deliver advantages such as energy efficiency, improved consistency and yield and reduced defects.

Sensor and control models are flexible, to suit your requirements, and operate as open advisory or closed loop systems which are secure and configured to maintain equipment and system performance within predetermined operational limits.

Hosokawa Gen4 continually analyses input and output intelligence and compares the actual plant performance with the predicted performance offered by the data model.

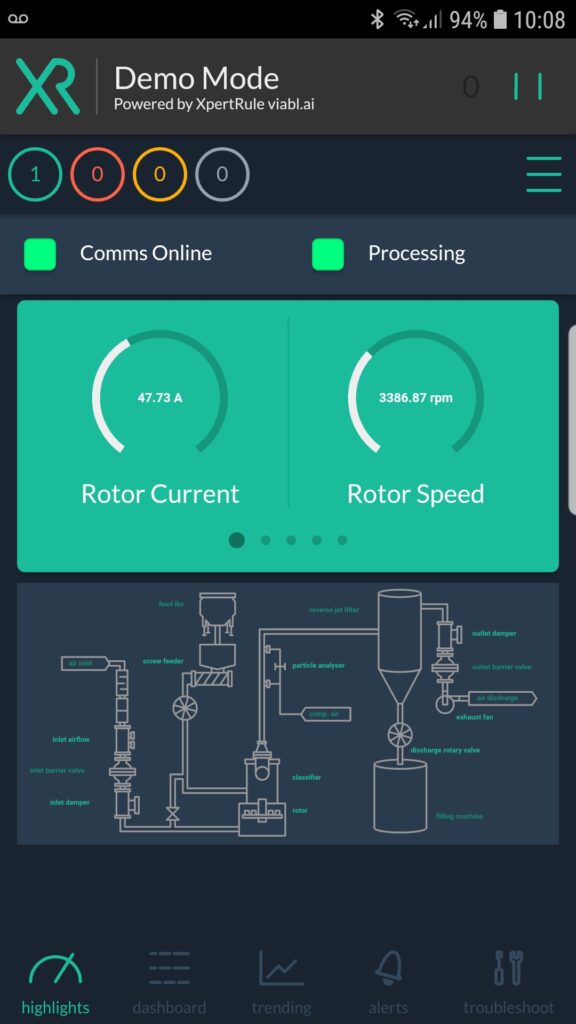

The use of Edge-based analytics allows for quicker and more transparent decision-making when connected devices, such as smart phones and tablets, are used to manage production processes and asset performance in real time.

This kind of capability would lead to reductions in unplanned equipment downtime, or the avoidance of downtime altogether, as well as a quicker start-up time.

The combined digital and manufacturing expertise of the Hosokawa Gen4 team means we are able to calculate process equipment and systems settings by analysing important independent and dependant process variables to learn the dynamic relationships between them.

Concurrent control between multiple variables, more intelligent asset utilisation, better activity synchronisation and process flows mean we can facilitate the enhancement of outcomes, leading to superior process and asset performance, as well as increased product consistency and quality, even in the production of small batches.

To see how sensor and control modelling could help your production processes and asset performance, our technology experts have created a demo version of the Hosokawa Gen4 ReMs App, specifically for process manufacturers to see how the technology could work for their business.

The demo version can be downloaded for free via the iTunes Store or on Google Play. Simply click here to download your preferred version.

To discover more about the services we can offer to support your Hosokawa Micron equipment, please get in touch with our helpful team. For immediate assistance or advice, feel free to give them a call on: