Hosokawa’s world-renowned Zirkoplex ZPS is a tried and trusted classifier mill used for a variety of practical applications in many industry sectors and is constantly being evaluated and improved to meet the needs of evolving processing requirements.

Known for its versatility, high performance, excellent throughput rates and energy efficiency, the Zirkoplex ZPS has the ability to safely and effortlessly grind and classify dry material into powders of varying fineness levels, from > 5µm to 200µm – including challenging adhesive products with a tendency to deposit, as well as hazardous and potentially explosive organic material. The Zirkoplex ZPS comprises an efficient impact beater mill with special steel grinding components and a multi-wheel ATP Turboplex ultrafine classifier for precise top-size limitation and boasts a number of excellent features that allow for the highest levels of hygiene and product integrity, such as cool grinding, fluidisation equipment, gentle processing and easy cleaning, which is perfect for the speedy introduction of different materials.

Conveniently available in a wide range of capacities, designs and powers, the Zirkoplex ZPS is ATEX-certified and can be used as a standalone piece of equipment or as part of a multi-processing machine or process system – including inside an Isolator, for situations which require containment during processing, such as in the pharmaceutical or battery industries.

The smallest Zirkoplex ZPS available is the laboratory-scale Picozirk (part of the Picoline series), which is perfect for fine milling very small quantities of soft to medium-hard dry material, including HAPIs, with a steep particle size distribution.

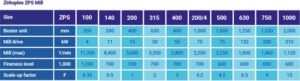

Currently, the Zirkoplex ZPS range comprises ten models with a drive capacity of between 4 and 315 kW. Each integrates a beater milling unit for precision fine grinding of the raw material and a unique ATP Turboplex multi-wheel air classifier to ensure a high-quality, consistent fineness of the final product.

There are a wide range of sizes, configurations, components and designs available to ideally match your processing requirements and our experienced team of processing experts and technologists are on-hand to offer advice, collaboration and even product trials to help ensure your mill will perform to optimal levels consistently and provides many years of cost-efficient and reliable service.

From extra-hard-wearing oxide ceramic wear protection coatings to GMP-standard, pressurised and pressure-compensated designs with specialist fluidisation components integrated at critical points in the equipment’s processing delivery, as well as easy accessibility for cleaning and maintenance, there are an array of elements that work together to provide optimal cool-temperature milling and classification of an enormous range of material, including the most challenging products.

For material which poses an explosive danger during processing, our Zirkoplex ZPS range is ATEX-certified in accordance with the EC type examination certificate No. IBExU03ATEX 1152 X and marked II 1 (i) D / 2 (o) DG c IIC T5.

In addition, we offer the Picozirk – from our Picoline series. Popular within the pharmaceutical and R&D sectors, it is ideal for processing tiny batches of material, such as HAPIs (with full-scale versions capable of processing several hundred kilos of essential pharmaceutical products per hour). For this purpose, a Hosokawa Micron Isolator can be made to order and uniquely tailored to your requirements to ensure operator safety and protect the environment.

The Zirkoplex ZPS is a high-performance mill and air classifier combination used for the deposit-free, ultra-fine processing of dry, soft to medium-hard materials, including challenging adhesive (sticky) products. Typically, the Zirkoplex ZPS handles a wide variety of chemicals, minerals, pharmaceuticals, pigments, metals and raw food ingredients (such as grains, malt, oats, rice, peas and soy beans) to create an enormous range of products and materials such as gelatine powder thickening agents to make jams, confectionery and tomato sauces, protein-rich powders, talcum powder, graphite for oven linings and pencils, carbon fibre, ceramics, filler, bread and muesli, pharmaceuticals, cosmetics, feed supplements, superglue and E-PVC polymers to make window frames, film and builders’ caulk.

The Zirkoplex ZPS is a great, energy-saving option for manufacturing lithium-ion batteries and can be used for rounding the synthetic graphite used in the battery material. The graphite is first pre-ground and is then rounded and classified in batches. The classifier mill has the capability to increase the tap density of the graphite to more than 1,000 g/L, allowing for better storage and charging capacity, as well as improved conductivity and battery life. The Zirkoplex ZPS offers high throughput of the graphite, variable fineness levels and typical synthetic graphite process yields of around 90%.

Hosokawa collaborates with and supplies the Zirkoplex ZPS to a large number of international milling companies that supply additives and food ingredients to the food industry, including the largest grain miller in Switzerland and long-term repeat customer, Farmesa, which processes soybean, one of the world’s most harvested grains. Installed in 2017, our Zirkoplex ZPS is used for the super-fine grinding of Farmesa’s extracted and extruded soy flakes, with soy processing being a tried and tested application for our customers for many years.

Concerned about the explosion risk associated with organic products below 500 microns, Farmesa required equipment that could be trusted to be reliable, safe and flexible, with explosion protection built in to safeguard operators from danger and protect both the equipment itself and the wider factory and environment. We collaborated with Farmesa from concept right through to completion, installation and commissioning, and our customer is delighted with the equipment’s efficiency, safety levels and the service they received from Hosokawa Micron Group.

The Hosokawa Alpine Zirkoplex ZPS conveniently performs two separate processes in one – size reduction and classification – and is available in a number of sizes to suit your application.

Firstly, the size reduction is achieved by the equipment’s efficient impact beater mill, which incorporates a triangular-ribbed grinding track in a segmented configuration, which is fixed in place and surrounds the grinding chamber, and impact beaters that are exchangeable. Material accesses the mill from the side, entering the filling socket where it is intercepted by high-performance impact beaters that are located on the beater disc. In collaboration with the grinding track, the beaters comminute the material.

When the material has been finely ground into particles – in accordance with the cutting settings that have been applied to the grinding mechanism – it makes its way via a rotary valve to the ATP Turboplex ultrafine classifier, whose chamber is located in the top section of the mill, where it is cooled and classified before exiting the Zirkoplex ZPS via the fines discharge. The classifier boasts multiple horizontal classifying wheels, allowing for an impressive throughput rate and an extremely consistent end product, while the air introduced into the equipment via an air inlet at the side of the equipment propels the material through the mill.

Material can also be introduced into the mill entrained in the air and in this case, the Zirkoplex performs its processing without the feed unit or else the feed unit can be closed, adding to its versatility.

Any particles that are too big are rejected by the classifying wheel and re-enter the impact beater mill again so they can be further reduced in size to meet the application’s fineness parameters. Finalised particles are separated from the air in a downstream system-sided collection unit.

To aide optimal performance levels, the Zirkoplex ZPS’s critical processing areas are equipped with a special fluidisation system and it boasts a high airflow rate that allows for cool grinding, which prevent the product from depositing. Where particularly abrasive products need to be processed, the Zirkoplex ZPS’s classifier wheel, fines discharge, grinding track and impact beaters can be coated in wear-protecting oxide ceramic.

Extremely user-friendly, energy-efficient and ergonomic, the Zirkoplex ZPS offers useful adjustable settings, allowing the operator to control the speed of the mill and also the speed of the classifying wheels, and is available in a number of sizes and configurations to suit your particular application. For further details, please take a look at the Specification section.

Hosokawa Micron’s milling experts can provide an extensive number of practical examples and technical data for multitude products and processing scenarios. Information is relatable to a wide range of processing industries, from food to minerals and cosmetics to pharmaceuticals.

Hosokawa Micron Ltd is a globally renowned powder processing company with more than a century of pioneering expertise and practical design and manufacturing experience, working on behalf of customers from a wide variety of manufacturing sectors for a diverse range of applications, including size reduction, classifying and containment.

The Zirkoplex ZPS classifier mill may be purchased as a standalone piece of equipment but may also be integrated into a Multi-Processing System. For the pharmaceutical industry, for example – where active ingredients (APIs) need to be processed but also contained, for the safety of the operator, environment and the material itself – the Zirkoplex ZPS can easily be integrated into a purpose-built, bespoke Hosokawa Micron Ltd containment Isolator.

Hosokawa Micron prides itself on its reputation and the quality of the equipment and process systems we design and manufacture. Projects are undertaken in-house, from concept to completion, by our team of highly experienced and knowledgeable product designers, technologists and engineers, project managed by a professional team boasting decades of first-hand process engineering and containment expertise.

Our valued experience extends to project planning, automation, installation and commissioning of complex process systems, which may comprise solely of Hosokawa-brand processing equipment or integrate third-party equipment – we are happy to collaborate on projects involving third-party equipment suppliers, if required.

To supplement the equipment itself, we also offer an array of lifecycle management services, such as genuine spare parts, servicing and maintenance by highly trained Hosokawa Micron maintenance engineers, upgrades, tailor-made optimisation software and training packages.

As part of the equipment concept and design phase, we are able to test your material to production level quantities at our dedicated technology centre – one of the largest facilities of its type in the world – to ensure your Zirkoplex ZPS is tailored specifically to the needs of your materials and application and will achieve optimal performance levels during processing.

Our experts have wide-ranging, first-hand expertise in mechanical process engineering and would be delighted to advise and guide you through your feasibility study, providing a range of advantages, including a neutral and solid view of the challenge and timely validation of your project, negating the risk of project failure and finding the best equipment or process system solution in line with your CAPEX and OPEX budget for machine investment.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on