The robust Hosokawa Alpine Ultraplex UPZ is, perhaps, the most adaptable fine impact mill available for wet and dry processing in this specialised market. Offering impressive levels of versatility, the mill can process hundreds of diverse raw materials and there are opportunities to configure the equipment for use as a pin mill or integrate the Ultraplex UPZ into a cryogenic milling process system, ideal for efficiently processing challenging raw materials.

Very popular with our global customers from the chemical, pharmaceutical, animal feed, mineral and food industries, the custom-made mill is simplicity itself to use, economical, reliable, technically advanced and is easy to access and maintain. Powder fineness is achievable in the range of 50µm to 5mm, thanks to the Ultraplex UPZ’s collection of easily interchangeable, wear-proof grinding elements, which effortlessly handle materials up to 3.5 Mohs hardness.

Currently available in a choice of ten sizes, there are many additional design features that can be employed to create an optimised, tailor-made milling solution. Process systems – incorporating additional equipment and features such as isolators and CIP/SIP systems – can be designed by our expert design and engineering teams for pharmaceutical and food-grade processing that meets the latest ATEX and cGMP standards.

For the creation of ultra-small batches of powder from soft to medium-hard raw material, the versatile Hosokawa Picoline series includes the Picoplex attachment, a mini-impact mill with a 40mm diameter rotor, perfect for R&D dry processing based on the Ultraplex UPZ.

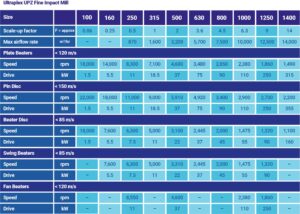

The Ultraplex UPZ fine impact mill is manufactured by Hosokawa Alpine – one of our sister companies, based in Germany – and is currently available in a range of ten models: 100, 160, 250, 315, 500, 630, 800, 1000, 1250 and 1400.

Constructed from mild steel or stainless-steel, the smaller versions have a cast housing with standard discharge (up to model 1000), but all models can have a welded housing with a standard or tangential discharge, if that is the preferable solution.

This mill is extremely versatile and can be supplied with a range of universal, easily interchangeable, wear-resistant milling elements that can cope with a range of material processing challenges. With the correct milling element fitted, the Ultraplex UPZ can produce powder material with either high fineness and a sharp top cut, low fines with good flow properties, high bulk density or high mass fraction within a defined particle size range. End product fineness is in the range of 50µm to 5mm, depending on the milling element chosen.

Milling Element Options

The Ultraplex UPZ is available in a range of designs and is configured to precisely meet the application it is required for, such as:

Optional Features

The Ultraplex UPZ is an extremely versatile fine impact mill that may be used in normal or cryogenic mode for wet or dry processing tasks. Popular in the chemical, pharmaceutical, food, mineral, plastic and animal feed industries, the equipment can reduce a huge variety of raw (even challenging) materials into consistent granular to ultra-fine powders with a high bulk density, high fineness with sharp top cut or high mass fraction. Cryogenic milling using an Ultraplex UPZ is perfect for the comminution of challenging materials, such as those that are fibrous, elastic, tough, hard, heat-sensitive, prone to oxidisation or are an explosion risk.

Typical end products and raw materials include fertilisers, paints, APIs, antibiotics and pharmaceutical excipients, herbal teas, sauces and soups, baby food, nutraceuticals, ground herbs and spices, dried vegetables, food colourings, gelatine, pectin, flour, sugar, modified starch, cork, PVC, polyamides, silicates, wax, mica, gypsum, seaweed, collagen, soya, salt and carbon black, which is used to make products such as tyres, batteries, printing ink and powder coatings.

The high-performance Hosokawa Ultraplex UPZ fine impact mill is an impressively versatile tailor-made option for the comminution of a wide range of materials into medium to ultra-fine powder between 5mm and 50µm, capable of processing a huge range of raw material up to 3.5 Mohs hardness and for the size reduction of challenging materials, including notoriously tricky cork and tough, fibrous spice roots.

One of the most popular aspects of the Ultraplex UPZ, is its universal design, which allows it to accommodate an excellent selection of interchangeable, heavy-duty, wear-resistant milling elements that provide diverse, wide-ranging processing results, from a high fineness with sharp top cut, to powders with high bulk density or high mass fraction within a defined particle size range. In addition to being a fine impact mill, the Ultraplex UPZ may also be adapted to become a pin mill (without a sieve), comprising one stationary and one rotating pin disc.

Raw material feeds into the equipment centrally via the mill’s door or inlet, where it enters the high-speed grinding chamber, which rotates and uses centrifugal force to efficiently disperse the raw material outwards against the chosen interchangeable milling element, which fractures the raw material particles into a powder or granular state.

The fineness of the powder produced is determined both by the milling element chosen and the mill’s adjustable speed, which for the larger machines means swapping out the belt pulley. For smaller models (up to 1000), the mill is driven by a frequency converter.

For many Ultraplex UPZ process systems, the raw material is usually fed via a hopper (or feed bin) into a feed metering unit and then a rotary valve prior to entering the mill itself. Thereafter, it exits the mill for further processing or collection. Please see the Ultraplex UPZ’s ‘Process System Solutions’ section for further information.

Interchangeable Milling Elements

Cryogenic Milling Systems

For materials that are not easy to mill into fine, free-flowing powders because they are tough, elastic, sensitive to heat or may be at risk of oxidation or even dust explosion, cryogenic milling is an excellent solution. Materials with characteristics that fall into this category include thermoplastics, elastomers, waxes, paint additives and even some metals.

Other raw products – such as various plastics, rubber granules, spices and high fat, low melting point baking aid mixes – benefit from being processed cryogenically. For example, by cryogenically grinding spices, you retain the spice aroma by minimising the loss of the spice’s essential oils and, in addition, see twice the performance from the mill when compared to conventional milling. When milled at an ambient temperature, the essential oil loss can be as much as 43%, while cryogenic milling typically results in a 3 to 10% loss. Alternatively, for spices with a high oil content (such as nutmeg, cloves or pepper), we would recommend a Hosokawa Contraplex CW pin mill.

The Ultraplex UPZ can easily be integrated into a cryogenic milling system to efficiently deal with these types of raw products. Prior to entering the Ultraplex UPZ, the raw material is cooled to the glass transition temperature while in the process system’s screw cooler (for a lower temperature) or directly into the mill, which is injected with liquid nitrogen or dry ice. The material becomes embrittled, which is necessary because of the elastic-viscous characteristics of some raw materials.

If the requisite stress at break of the brittle material is above that of the elastic material, the amount of energy required to mill the material is much lower, which means that the liquid nitrogen-cooled system and material, for example, can be processed by the impact mill much quicker than normal (typically two to three times quicker), even to high particle fineness values, which is much more efficient and economical.

An automatic quick-change filter would normally also be integrated, while a system control cabinet, and fan would also be included as part of the system. Temperature sensors would be fitted at the material discharge point.

Wet Processing

For materials that require wet comminution, a specially designed Ultraplex UPZ is required, which incorporates special mill bearing seals, a gas tight and pressure-proof design to 0.3 bar overpressure and is constructed from special (certified) materials.

A Hosokawa Alpine Ultraplex UPZ 1400 impact mill, fitted with a plate beater unit, is an excellent and very popular, solution for wet processing tasks, including the processing of Polyoxymethylene (POM). This model typically achieves a throughput of 5 to 10 tonnes per hour of solid material, depending on the product fineness required, as well as 5 to 10 tonnes per hour of the liquid component, depending on the throughput of the solid component.

Example Application Materials

Chemicals: Fertilisers, pesticides, paints and pigments, general chemicals including solid acids, salts, silicates, wax, resins, carbon black, stearates, sulphates, phosphates etc

Pharmaceuticals and Nutraceuticals: Antibiotics, excipients, herbal teas, roots, senna pods, hibiscus, sage, rose hips, raspberry and blackberry leaves, camomile etc

Herbs and Spices: Rosemary, celandine, saffron, celery, onions, pepperwort, parsley, turmeric etc

Food and Confectionery: Bakery product rejects, oat flakes, potato flakes, casein, baby food, skimmed milk powder, cake mix flour, dried fruits, pasta rejects, mushrooms, sugar, starch, gelatine, pectin, flavouring agents, food colouring etc

Animal Feed: Soy flour, freeze-dried meat, corn cobs, pea pods, pea fibre, extruded cereal such as barley, wheat, rye, draff, pomace, marc, molasses, clay, pulp, sugar beet parings etc

Minerals: Gypsum, limestone, kieselguhr, expanded perlite etc

Plastics: Polyamides, PVC, PTFE, PE etc (under normal temperatures or in cryogenic milling mode)

The Ultraplex UPZ is a very popular piece of milling equipment that can be supplied as a standalone machine or can be integrated into a process system comprising other Hosokawa equipment (or third-party equipment, if necessary).

Hosokawa Micron supplies a variety of ancillary process system equipment, including hoppers, exhaust fans, control cabinets, state-of-the-art sensors, filters, heat exchangers and rotary valves to provide a complete bespoke solution designed, engineered and manufactured in-house to meet your precise requirements.

The Japanese Hosokawa Micron Group is a pioneering and world-leading processing expert that has been established for well over a century, with a network of technical, manufacturing and sales office bases all over the world, including North and South America, Europe and Asia.

Powder processing is where we really excel and we are lucky to have amassed a wealth of scientific knowledge and practical design, engineering and manufacturing expertise that means we have become one of the world’s foremost processing specialists, including for highly specialised containment equipment such as isolators, sterile isolators, gloveboxes and downflow booths.

Containment equipment can be critical as a complementary piece of processing equipment for industries such as cosmetics, pharmaceuticals, food and chemicals, which routinely use powdered material to manufacture products such as medicines, mineral and powder-based make-up, fertilisers, herbs and spices, granulated and powder coffee, sugar, flour, baby formula and lithium-ion batteries.

We are commissioned and trusted by some of the world’s largest blue-chip companies from a wide variety of manufacturing industries to supply not only the finest high-performance processing equipment and systems, but also apply our expertise to provide bespoke solutions via product trials, feasibility studies, production scale-up, new product development and process optimisation, as well as invent specialist, tailor-made designs that address challenging processing requirements, such as for hazardous and explosive materials, as well as abrasive, heat-sensitive or sticky raw products.

The European-based Hosokawa Micron Group companies have, between them, a huge portfolio of equipment for milling, classifying, sieving, particle design, shredding, pressing, crushing and lab work, which are supplemented by specialist equipment for containing these processes to protect operators, the environment and the product integrity.

We often collaborate with our sister companies on projects to allow us to provide a more comprehensive service, more in-depth specialist knowledge and a wider portfolio of processing equipment, particularly when a process system is required.

Our technical, design, engineering and manufacturing experts are adept at working with customers to tailor-make the optimal high-performance equipment or process system for a processing operation.

Specialist Milling Systems

For complex hazardous and explosive material processing, we offer a range of tailor-made containment solutions that are designed and manufactured to meet (and even exceed) the latest industry standards. Typically, these would include a sterile isolator or an isolator (depending on the process and application), which are manufactured to comply with the latest ATEX guidelines.

We also have in-depth and extensive experience creating specialist food and pharma-grade process systems that require very gentle processing techniques for fragile materials such as lactose, which is a popular ingredient in many foodstuffs and as an excipient in pharmaceutical inhalers, for example.

Cryogenic Milling Systems

For materials that are not easy to mill because they are tough, heat-sensitive, elastic or may even be at risk of oxidation or dust explosion, cryogenic milling is an excellent solution. The Ultraplex UPZ can easily be integrated into a cryogenic milling system, featuring temperature sensors, a system control cabinet, fan and screw cooler with liquid nitrogen or dry ice supply that allows for processing at a high stressing speed and short stressing cycle.

There are many advantages to powder processing using a cryogenic milling system with in-circuit gas mode and Hosokawa Micron is an expert technical partner to collaborate with when designing a system for optimal cryogenic processing performance. For information about the technicalities of the cryogenic milling process, please see our Ultraplex UPZ ‘How Does It Work?’ section or feel free to contact our milling experts for advice or further information.

Hosokawa Micron Group’s experienced engineers and laboratory technicians perform hundreds of product trials every year on behalf of customers from all over the world, including feasibility studies, process optimisation and scale-up, right through to new product development and creating specialist, bespoke equipment designs to meet specific or challenging technical requirements.

With state-of-the-art 3,000m2 facilities and the latest models of our industry-leading processing equipment available, we can offer customers a thorough and wide-ranging service, including real-time remote monitoring using dedicated Hosokawa software, on-line meetings, product sample inspection and laboratory analysis (via video link if an in-person, on-site visit isn’t feasible). Product trials may be carried out at laboratory or production scale and are underpinned by comprehensive testing documentation and reference samples of the milled end product. Cryogenic milling testing is available, using an Ultraplex UPZ 315, which we also use for our own contract manufacturing projects.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on