The In-line Disintegrator from Hosokawa Micron Ltd is a compact, robust piece of equipment for the effective processing of liquids, slurries and suspensions and is based on the well-proven technology of Hosokawa’s Vertical Disintegrator (RD). Part of Hosokawa’s versatile disintegrator range – which includes the Angle Disintegrator, Vertical Disintegrator and Horizontal Disintegrator – the In-line Disintegrator is trusted by homecare companies, who use it to help manufacture brands of washing powder and dishwasher tablet.

The In-line Disintegrator (RI) is also used by the specialist chemical industry for processing sticky materials such as latex, e-PVC, sulphur and vinyl emulsions. Offering size reduction, dispersion, de-lumping, grinding and mixing capabilities, other useful features of the In-line Disintegrator include the easy access chamber and easy removal of the perforated reduction screen and hammers, which makes the cleaning and maintenance of the equipment much easier.

The In-line Disintegrator is perfect for processing a variety of chemicals, particularly excelling in powder processing for products such as dishwasher tablets and soap powder.

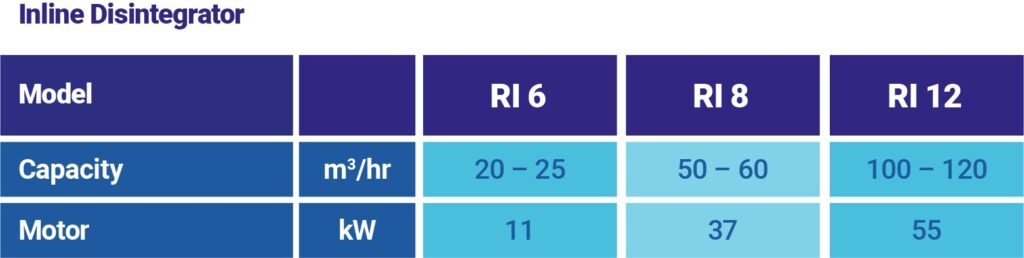

Available in three models (RI 6, RI 8 and RI 12), the In-line Disintegrator models have a power range of between 15kW and 55kW. The least powerful version (RI6) can process up to 25 cubic metres per hour, while the most powerful model (the RI 12) is capable of processing up to 130 cubic metres per hour, powered by its 55kW motor. All models have a 10 barg pressure rating.

Hosokawa Micron offers a range of Disintegrator products that, between them, are suitable for processing a huge number of materials for the pharmaceutical, chemical, food and beverage, homecare, rubber, plastics and wallpaper industries. Materials suitable for processing by the Vertical Disintegrator, Angle Disintegrator and Horizontal Disintegrator include paper pulp, aramid fibre, frozen meat, vegetables, fruit, resin, bone, barley malt, botanical extracts, viscose, cellulose, pigments, uranium powder, cheese, chocolate, tobacco, garlic, ginger, blood, coffee, fat, dye, paint, petrochemical sludge, minerals and alginates.

Please contact the expert sales team at Hosokawa Micron Ltd, who would be delighted to provide advice and information on the most suitable Disintegrator and process system for your requirements.

Hosokawa Micron’s In-line Disintegrator is used for the continuous processing of liquids with high viscosity, pastes and suspensions to manufacture soaps and detergents and process specialist chemical materials, including latex, e-PVC, sulphur and vinyl emulsion by de-lumping, grinding, size reduction and dispersing. The detergent and pigment industries rely on the equipment to effectively stop their materials from blocking the spray drying process.

The Hosokawa Micron In-line Disintegrator is pressure rated to permit installation within pipe systems to 10 barg operational pressure. ATEX-certified In-line Disintegrators are also available for explosive area installations

The In-line Disintegrator effectively disperses, de-agglomerates and reduces materials that are fed into it, repeatedly subjecting the material to impact and attritional forces that cause high turbulence and a high shear rate. It’s versatile design and technology means it is suitable to process a variety of materials for industries, including homecare and speciality chemicals.

The In-line Disintegrator has a rotor mounted onto a vertical or horizontal shaft and a primary screen that entirely surrounds the rotor. Material enters and rotates in the grinding chamber and is kept in situ by an upper feed hammer and bottom feed hammer until the rotor and hammers have completed their processing cycle. The processed material exits through a 360° perforated screen basket, discharging via the circumference of the machine through to the next stage of processing.

Gland packing or mechanical seals can be chosen depending on the customer requirement. Mechanical seals can be either single, double or paired ‘back-to-back’ designs, depending on the process and application.

The In-line Disintegrator from Hosokawa Micron Ltd may be used as part of a process system that can be tailor-made for a specific purpose, depending on customer requirements. With two versatile options for the shaft seal (gland packing and mechanical seal), this model of disintegrator may be installed as part of an in-line production process for pastes, slurries and other liquid materials. Components to work alongside the In-line Disintegrator can include feed tanks, pumps, spray dryers, blowers, filling and weighing systems and control cabinets.

Hosokawa Micron Ltd boasts decades of expertise designing, engineering and manufacturing reliable, efficient and complex process systems for customers from a wide range of manufacturing sectors, including pharmaceuticals, chemicals, food and beverage and soaps and detergents. Our powder processing knowledge is second to none and combines more than a century of pioneering innovation around processing technology, including scientific, technical and mechanical engineering expertise.

Our service includes everything from design studies and product testing, to engineering, manufacture, installation and commissioning. A wide range of dedicated lifecycle and digitalisation services augment the diligent and reliable customer service we also offer.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment