The Hosokawa Micron Extructor is an energy-efficient, robust size reduction machine suitable for cutting and shearing course materials including frozen blocks of food and blood plasma, as well as dairy products, soaps and polymer gels. The Extructor performs in a similar way to a Hosokawa Micron Pre-Breaker, but comprises fewer internal tools and a shorter barrel, which helps to ensure the materials being processed maintain their integrity without degrading and bruising. Conveniently, the Extructor has five models in its range – offering flexibility of scale, speed and the amount/weight of material that may be processed per hour – and can be tailor-made to suit customer specifications.

To meet a wider range of processing and industry demands, we recommend the Hosokawa Micron Pre-Breaker, a similar product for performing size reduction operations, which is available in a number of more powerful, larger versions.

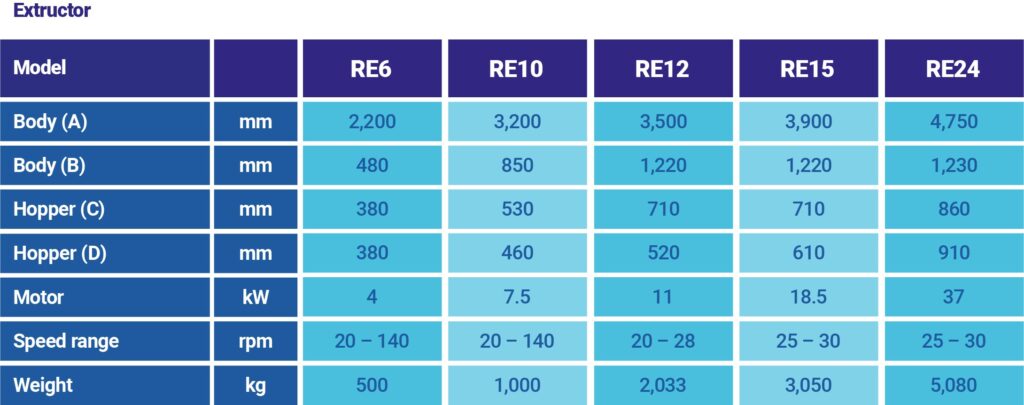

The Hosokawa Micron Extructor is available in five models (RE6, RE10, RE12, RE15 and RE24), which offer a range of power, size and speed options.

The Hosokawa Micron Extructor is used for carefully reducing the size of raw materials. The equipment can be used for processing frozen blocks of fruit, fish, meat, tomatoes and liquid primary pharmaceuticals (blood plasma), as well as blocks of cocoa, making high-end pet food, potato ricing, making scrap bar soap, processing butter and cheese, along with polymer gel for use in water treatment.

Hosokawa Micron Extructors are used by customers worldwide, including France’s largest processor of fresh and frozen vegetables, Europe’s largest supplier of processed cheese to the fast-food industry, a high-end pet food manufacturer and multiple customers in China and the Far East, who use the Extructor for blood plasma reduction during the manufacturing of human vaccines and to process ingredients for chewable indigestion tablets.

Hosokawa Micron’s Extructor effortlessly processes a range of frozen and ambient materials by reducing their size using an efficient hammer and anvil action.

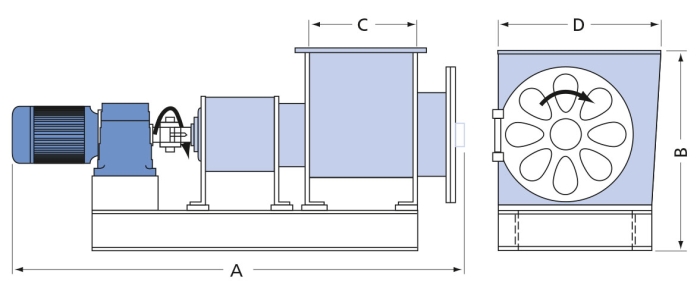

The raw material enters the Extructor via the inlet hopper and progresses into the processing chamber, transported via the rotation of the horizontal shaft. The forward-progressing hammers and relatively small anvils built into the barrel section of the Extructor cut and shear the product (without bruising or damaging it) as they rotate at a chosen speed, before conveying the processed material through a choice of orifice plates and out through the discharge section for further processing, if required.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment