Hosokawa Alpine’s versatile, energy-saving Gear Pelletiser AGF offers a compelling solution to the challenges of transforming fine powder into dust-free, high-quality pelletised products with improved handling, dosing and storage properties, which is ideal for the production of products such as pharmaceuticals, animal feed, ceramics, agricultural chemicals and various resins and plastics.

Using a low-pressure agglomeration method, minimal amounts of binder and very efficient counter-rotating rollers, in either batch or continuous mode, the robust Gear Pelletiser AGF generates excellent shear forces and is suitable for processing a vast array of powders and particles with diverse characteristics, particle size distributions and moisture contents. Even original material that has poor flowability and is difficult to dose or is adversely affected by temperature change, for example, can be effortlessly processed into cylindrical, stable pellets of uniform length, diameter and smoothness.

With a choice of fixed or exchangeable nozzle types of multiple designs, shapes and widths – from 1mm to 10mm in diameter – plus the ability to operate with the addition of inert gas and when using solvents – diverse pellet formats are achievable. The compressing pellets can even be through-hardened or hardened just on the surface, depending on your requirements.

Equipped with the latest technology and ergonomically designed and engineered for easy access, maintenance, cleaning and the exchange of nozzles, if applicable, the Gear Pelletiser AGF reassuringly meets the exacting demands of the pharmaceutical industry and conforms to FDA standards.

The Gear Pelletiser AGF range is an excellent solution for compressing and extruding materials into a variety of dust-free cylindrical formats, using low pressure and a small amount of binder to create high-quality, stable pellets with a diameter range of between 1mm and 10mm.

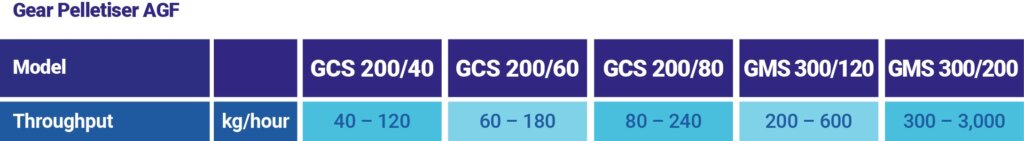

Currently available in five models of differing sizes, the range is divided into GMS and GCS categories – depending on whether the equipment has a mill shaft or cantilevered shaft – and conveniently offers throughputs of between 40 and 3,000 kilograms per hour, which consequently gives greater flexibility for accurate scale-up, if and when required.

A selection of ancillary equipment is available to complement the Gear Pelletiser AGF, including agitating feed hoppers for raw materials that flow particularly poorly and gasketed covers, ensuring dust-free operation.

The adaptable, high-performance Hosokawa Alpine Gear Pelletiser AGF range is ideal for the pelleting requirements of a number of industries, which can utilise the compression equipment for making pelleted pharmaceuticals, agricultural chemicals, food, synthetic resins, rubber chemicals, ceramics, catalysts, plastic additives and animal feed, amongst many other products.

The Gear Pelletiser AGF is popular for processing pre-crushed polymer flakes into dust-free pellets, which is just one example of how the equipment effortlessly overcomes issues of processing challenging materials that may be difficult to dose or can be adversely affected by temperature changes. Often, the Gear Pelletiser AGF is employed prior to a secondary spheronisation process.

Robust, high-quality construction from stainless-steel

Hosokawa Micron Group designs and manufactures a wide range of pelleting machines, basket extruders and spheronisation equipment suitable for creating the highest-quality extruded material and is available as standalone equipment or as part of a process system.

For cylindrical pellets to be formed, the Hosokawa Alpine Gear Pelletiser AGF is the best equipment solution, while for highly porous, shingled material that requires a loose structure, large surface area and good dispersal properties, the Hosokawa Alpine Bextruder ABX is recommended. Material is pressed using a perforated die and an extrusion rotor.

For further post-pelletising spheronisation, we recommend the Hosokawa Alpine Bexroller ABR. This equipment is particularly suitable for highly active pharmaceuticals and aggressive chemicals.

In addition, we offer a number of pieces of equipment and process systems for compaction – such as roller presses as well as the Hosokawa Micron BV Extrudomix, which is an economical, multi-functional high-shear mixer and extruder, popular for processing homogenised powders with liquids into plastic masses, then extruding the homogenised material. The equipment may be used as part of a complex, sustainable process system tailor-made specifically for your requirements.

For further information regarding our ranges of extrusion equipment, tailor-made process systems and wider portfolio of processing equipment for powders and particles – including gas-tight and ATEX, FDA and GMP-compliant designs, simply get in touch via our enquiry form or give us a ring on +44 (0)1928 755100.

The Hosokawa Alpine Gear Pelletiser AGF is a versatile extruder for batch or continuous processing tasks, exerting low pressure – with the addition of a small amount of liquid binder – to create a variety of pelleted material of uniform characteristics that can be entirely hardened or hardened just on the outside.

The equipment’s technical components comprise a choice of static or agitating feed hopper (depending on the flowability of the material to be processed), a product chamber and two counter-rotating hollow-toothed rollers with a selection of nozzle bores to produce high-quality pellets of between 1mm to 10mm in diameter.

The Gear Pelletiser AGF can be made dust and gas-tight with the addition of a gasketed cover. Conveniently, purging with inert gas and the addition of solvents is possible and creates no operating issues.

Raw powder material enters the Gear Pelletiser AGF from the attached hopper, located above the processing chamber. Gravity (with the addition of agitation if necessary) pulls the material down through the top of the conical processing chamber, where it contacts a set of two counter-rotating rollers. The rotating rollers force the material to pass through a set of nozzle bores or press nozzles, which are fixed between the hollow teeth of the rollers. As the material is introduced into the channels of the chambers it densifies and becomes cylinder-shaped pellets that emerge on the inside of the rollers. Densification of the material is determined by the ratio of the nozzle diameter to its length. The addition of counterbores enables the nozzle length to be shortened, if necessary.

The rollers can be designed with solid fixed extrusion walls, featuring standard or short nozzles, or designed with exchangeable nozzle inserts, which can also be of a standard or short length. Tooth shape, nozzle diameter and nozzle length can be chosen for optimal performance in consideration of the material to be processed. If and when product changeover is required and a different type of nozzle is needed, the inserts can be quickly and easily exchanged.

Rollers are sealed at both sides by cheek plates to counter against material escaping laterally and a suitable roller bearing is used for optimal performance. GMS models use a mill shaft to drive the rollers, while GCS models have cantilevered shafts.

To enable the most efficient product discharge and highest product yield, adjustable cutting knives are installed inside the hollow rollers, which are easy to access for cleaning and maintenance purposes. Gravity helps to discharge the material from the bottom of the chamber to enable further processing if required – such as cooling, classification, size reduction, sieving or spheronisation – or bulk collection into a filling and weighing system or drum and bulk container handling equipment (which Hosokawa Micron Ltd can engineer, build and supply to meet your requirements).

For further information about the bulk container handling equipment and filling and weighing systems we can design and manufacture for your Gear Pelletiser AGF, please click here.

The Hosokawa Alpine Gear Pelletiser AGF range can be supplied as an individual piece of versatile low-pressure press agglomeration equipment but may also be supplied as part of a larger, bespoke process system designed, engineered and manufactured by Hosokawa Micron Group to precisely cater for your specific application, material and requirements.

Our compaction equipment excels at producing uniform cylindrical pellets with a smooth surface, but if a secondary spheronisation process is required, we offer the perfect equipment solution, which can be integrated alongside the Gear Pelletiser AGF to create an entirely bespoke process system, which may also comprise additional upstream and downstream equipment, such as classifiers, flake crushers, sieves and driers, as well as dust and fines recycling apparatus.

Hosokawa Micron Group is a world-leading expert in the processing of powders, particles, liquids and other materials, including materials that are (or can become) an explosion risk. Our industry-leading equipment and process systems across the entire portfolio combine high-quality construction materials, aesthetic, practical and ergonomic design and engineering, plus the latest technology and processing theory, with all equipment and process systems meeting and even exceeding current European and international safety standards.

Offering one of the most diverse portfolio ranges available for powder and particle processing, our efficient and robust equipment and process systems are chosen by SME and blue-chip companies across the globe, from industries including pharmaceuticals, chemicals, cosmetics, food and beverages, minerals, nuclear, plastics, rubber, powder coatings, toner engineering and recycling.

A first-class in-house project management and engineering service, along with in-house technical services – such as contract manufacturing, particle design, process testing, process optimisation and material testing – offer you an entirely professional solution to match our adaptable high-performance products and the process systems that we can precisely engineer and tailor-make for you.

Our wealth of knowledge and expertise encompasses every stage of the processing of your raw material, from R&D, feasibility studies and testing, even as far as conveying, weighing, dosing, storing and delivering your processed bulk solid material in the most efficient, clean, hygienic and safe way. For further information about the bulk container handling equipment and filling and weighing systems we can tailor-make to complement your Gear Pelletiser AGF, please click here.

As you would expect, the equipment portfolio is also underpinned by extensive lifecycle management services and friendly, efficient customer care to support you during the decades of service you can expect to enjoy from Hosokawa Micron Group equipment and process systems.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on