Hosokawa Micron Group’s innovative, multi-application Flake Crusher AFC is a stainless-steel screen granulator offering a highly effective, energy-efficient way of gently processing brittle and fragile materials into virtually dust-free, high-quality granulate with a particle size range between 0.5mm and 10mm.

Ideal for use in hazardous dust areas – due to its circumferential speed of approximately 1 m/s – the Flake Crusher AFC’s capabilities are numerous and include deagglomerating, increasing bulk density, disintegrating agglomerates, improving material flowability of clumped and bulk materials, homogenising mixtures, recycling tablets and dust-free crushing soft to medium-hard materials, such as lump salt and hygroscopic substances.

The Flake Crusher AFC range is commonly integrated into process systems comprising our specialist roller presses, such as the Hosokawa Alpine Pharmapaktor APC C, and plays an important role in preparing high-quality APIs for producing tablets and filled capsules in the pharmaceutical sector. It is also favoured by a multitude of other processing industries, who appreciate the equipment for its superior performance, simplicity, versatility, cost-effectiveness, extremely low maintenance requirements and short turnaround times during screen changing and cleaning.

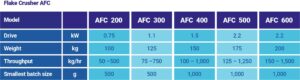

The Flake Crusher AFC is a multi-purpose, compact piece of size reduction equipment often used in tandem with a roller press and isolator as part of an agglomeration process system. Conveniently, the crusher is available in a range of five sizes – with models capable of producing throughput of between 500kg and 1,500kg per hour – and can be configured and equipped to effortlessly perform a host of crushing tasks. Producing granulate material of the very highest standard, particle sizes can be achieved between 0.5mm and 10mm, depending on requirements.

Due to its gentle processing capability, which is perfect for fragile and brittle material, the Flake Crusher AFC is particularly favoured by manufacturers whose processes could be potentially hazardous due to dust creation, particularly those from the food and beverage, chemical and pharmaceutical industries, providing a typical circumferential speed of around 1m/s. Dust-free processing is easily achievable when using the Hosokawa Alpine Flake Crusher AFC.

In addition, design options are available for CIP/WIP functionality, while the equipment can also be made inert, if required.

Optional Features

The Hosokawa Alpine Flake Crusher AFC offers a versatile range of applications, such as gently and highly effectively grinding fragile soft to medium-hard materials, homogenising mixtures, increasing bulk density, disintegrating agglomerates, recycling tablets and improving flowability of materials that are clumped together or have poor flow properties. Suitable for many industries, the screen granulator is instrumental in processing everything from high-quality detergents, active pharmaceutical ingredients, excipients, colour pigments, silicone and mineral powders, to herbs, peas, vitamins, milk powder, soya, animal feed, fish meal, food seasonings, dried fruit and proteins.

The high-performance Flake Crusher AFC is a compact, well-built piece of equipment for the size reduction of brittle, easily breakable material using a slow and gentle crushing action. Particle sizes are in the range of 0.5mm to 10mm.

Versatility is one of the great advantages of this screen granulator, with well-thought-out technology allowing for applications including general deagglomerating, deagglomerating following drying and mixing operations, homogenising mixtures, crushing flakes to granulate, increasing bulk density of material, crushing soft to medium-hard materials (including stipulating the top cut, in the case of rejects), increasing clumped material flowability (such as lumped salts and hygroscopic substances), improving the flowability of bulk materials and recycling tablets.

Designed specifically to meet the latest industry processing requirements, the Flake Crusher AFC has universal appeal to many manufacturing sectors due to its gentle handling of a wide range of materials and dust-free processing capabilities, which allows the equipment to be safely used in hazardous dust areas.

The Flake Crusher AFC is available in a range of sizes and has a very simple operation. Material is introduced into the upper area of the equipment and falls into its horizontally orientated grinding chamber, where a rotating grinding tool conveys the material downwards through either a sieve mesh, a screen featuring rasp-like perforations or a grinding sheet. The mesh width of the screen dictates the final particle size of the material (which would be in the range of 0.5mm to 10mm) and is achieved by the rotating or oscillating crushing motion of the rotor. The low peripheral speed of the Flake Crusher AFC is typically around 1 m/s, helping to ensure gentle, dust-free processing.

Thanks to the expertly engineered design of the equipment, the Flake Crusher AFC is very user-friendly and low maintenance. Screen changes and cleaning are achievable in quick time, so downtime is reduced to a minimum.

Agglomeration Process Systems

The Flake Crusher AFC is a popular component of an agglomeration process system, typically comprising a roller press such as a Pharmapaktor APC C, containment isolator, powder conveying equipment, filling and weighing system and the flake crusher itself. Popular in the pharmaceutical, food and chemicals sectors, these tailor-made process systems are robust and integrate the very latest technology for managing and assessing the performance of the equipment. Capable of processing a huge variety of materials, including highly hygroscopic antibiotic material, the systems can also improve the kneading ability and densification of products such as tea, salt, sugar, effervescent powder, Teflon and battery materials.

Hosokawa Alpine’s Flake Crusher AFC can be supplied as an individual piece of equipment but can also be supplied as part of a larger process system, for example when partnered with a specialist Pharmapaktor APC C roller press to process APIs (active pharmaceutical ingredients) or in conjunction with other multi-purpose roller presses available from the Hosokawa Micron Group product portfolio.

Due to its gentle milling capability, the Flake Crusher AFC is extremely popular with manufacturers whose processes could be hazardous due to dust creation, such as those from the food and beverage, chemical and pharmaceutical industries – dust-free processing is easily achievable with the Flake Crusher AFC. Options are also available for CIP/WIP functionality, while the equipment can also be made inert, if required, so there are many advantages to choosing Hosokawa-brand compaction equipment for use in hazardous dust areas.

Hosokawa Micron Group is a powder processing expert with many decades of first-hand experience in the scientific, technical and mechanical aspects of optimal equipment performance. Trusted throughout the world by leading manufacturing companies across multiple sectors and disciplines, we are renowned for innovating ground-breaking processing equipment and complex process systems to create and handle bulk and small batch powders, particles, liquids, vapours and all manner of raw materials from foodstuffs to rubber and plastics. Our equipment and systems expertise are underscored by a first-class project management and engineering service – from initial design conception to equipment delivery and commissioning – plus extensive lifecycle management services and aftersales customer care.

The Flake Crusher AFC by Hosokawa Alpine is an essential piece of equipment in the highly demanding pharmaceuticals industry, where it plays a vital role in crushing challenging active substances (in the form of flakes or pellets) into high-quality, dust-free granulate used to manufacture tabletted pills or to fill pharmaceutical capsules or medicine sachets. The equipment is integrated as standard into our popular Pharmapaktor APC C roller press range, designed specifically for the pharmaceutical industry.

Importantly for the pharmaceutical industry, the stainless-steel Flake Crusher AFC is the perfect partner to the Pharmapaktor APC C and holds its own in terms of processing highly potent hygroscopic material into free-flowing granulate with a high bulk density that is dust-free and, therefore, less hazardous to the environment and operators.

The dust-tight Pharmapaktor APC C offers numerous process, design and handling advantages and can be equipped with the very latest, state-of-the-art isolator technology to create an agglomeration process system to OEB 5 level that meets exacting ATEX, FDA and GAMP-5 standards. As with the Flake Crusher AFC itself, the roller press can be designed to have an inert operating mode, if required.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on