The innovative Hosokawa Micron Active Freeze Dryer (AFD) is a compact batch dryer that provides one-of-a-kind opportunities for efficiently producing high-quality, consistent sterile bulk pharmaceuticals in a single process, resulting in a fine loose powder that can be collected directly from the product collector with minimal handling required from the operator. A wide range of material consistencies can be handled by the Active Freeze Dryer, from solutions, dispersions and pastes to wet solids, which is perfect for processing antibiotics, APIs and electrolytes, along with protein, collagen, plastics, ceramics, nanomaterials and glass powder.

Traditional tray freeze dryers are labour intensive, but the new technology integrated into Hosokawa’s cutting-edge Active freeze Dryer is a significant advancement in the field of freeze-drying thermo-sensitive bulk solids and powders. Conveniently, various product characteristics can be improved by Hosokawa’s Active Freeze Dryer, using an agitated freeze-drying process and without the need for additional post-processing procedures. The Active Freeze Dryer from Hosokawa Micron is also more economical, efficient and compact than traditional tray dryers, quickly and simply producing excellent-quality, lump-free powders.

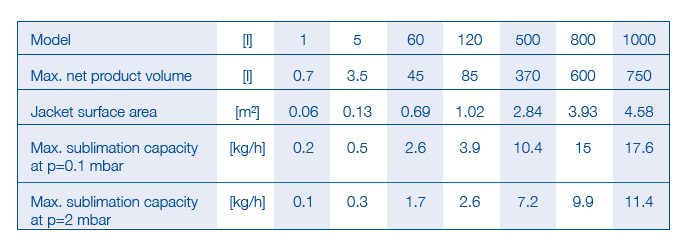

Active Freeze Drying Specifications

Available in a range of nine models – from 1 litre to 1,000 litres – the Hosokawa Micron Active Freeze Dryer can be used as a standalone piece of equipment or integrated into a freeze-drying process system. Please get in touch if you would like further information on the models available.

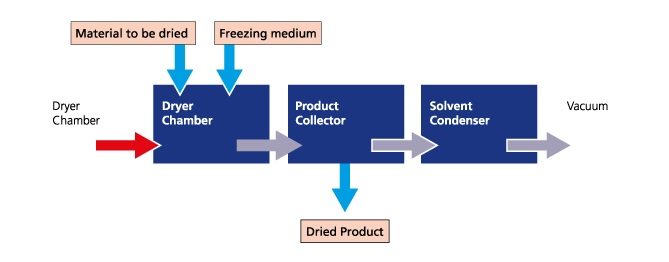

In addition to the freeze-drying chamber, the Active freeze Dryer system can include one or more of the following components, depending on customer requirements:

Optional Features

The unique Active Freeze Dryer produces fine, loose powder and is used mainly for sterile bulk pharmaceutical applications, including APIs and antibiotics, as well as health and sports nutrition applications such as collagen, protein, lipids and electrolytes. The batch dryer can also process a wide range of other materials, insects, fibre, polymers, ceramics, catalysts and nanomaterials.

Produces high-quality, lump-free, free-flowing powders in a single process

Active Freeze Drying

Hosokawa Micron’s stirred freeze drying technology incorporates the use of a jacketed and stirred Nauta® conical vacuum dryer operated at low temperature and pressure to produce lump free, free flowing product.

The Active Freeze Dryer consists of a specially designed drying chamber and collection filter. In the chamber the material to be dried is frozen very quickly with the aid of a freezing medium. During the subsequent sublimation the heat is applied throughout the jacket and efficiently distributed throughout the product by the stirrer. The initially coarse granules will gradually reduce in size due to the sublimation of the connecting ice structure between the frozen material. The released dried particles will make up a loose powder moving to the filter.

Typical Applications of Active Freeze Drying:

The product is first dynamically frozen in the specifically designed chamber of the Active Freeze Dryer. The motion inside this chamber guarantees that materials will quickly freeze into free-flowing solid granules, despite their initial state (liquid, granular, solid or paste). After the product is completely frozen, a deep vacuum is introduced so the sublimation process can begin.

The heat that is provided by the jacket of the machine and is distributed evenly throughout the product. As the ice structure connecting the frozen material sublimes, the coarse frozen granules gradually decrease, yielding a loose powder comprised of fine, dry particles.

As the solvent disappears, the product temperature rises until it reaches the jacket temperature, reaching the final step in the drying process. The chamber is opened once the vacuum has been released so the powdered product can be discharged.

Browse though the Hosokawa Micron product catalogue to view all of our innovative processing equipment or contact us directly on